Chomerics THERM-A-GAP PAD 30 and THERM-A-GAP PAD 60 Thermally Conductive Gap Filler Pads

Our team at KR Anderson, Inc works with highest quality thermal interface materials. We apply our years of expertise to select only the most reliable products for your project. Chomerics THERM-A-GAP thermal gap pads are a trusted leader in TIMs providing a range of solutions. The newly released Chomerics THERM-A-GAP PAD 30 and THERM-A-GAP PAD 60 are materials to be excited about.

Why work with THERM-A-GAP PAD 30 and THERM-A-GAP PAD 60?

Value and Performance

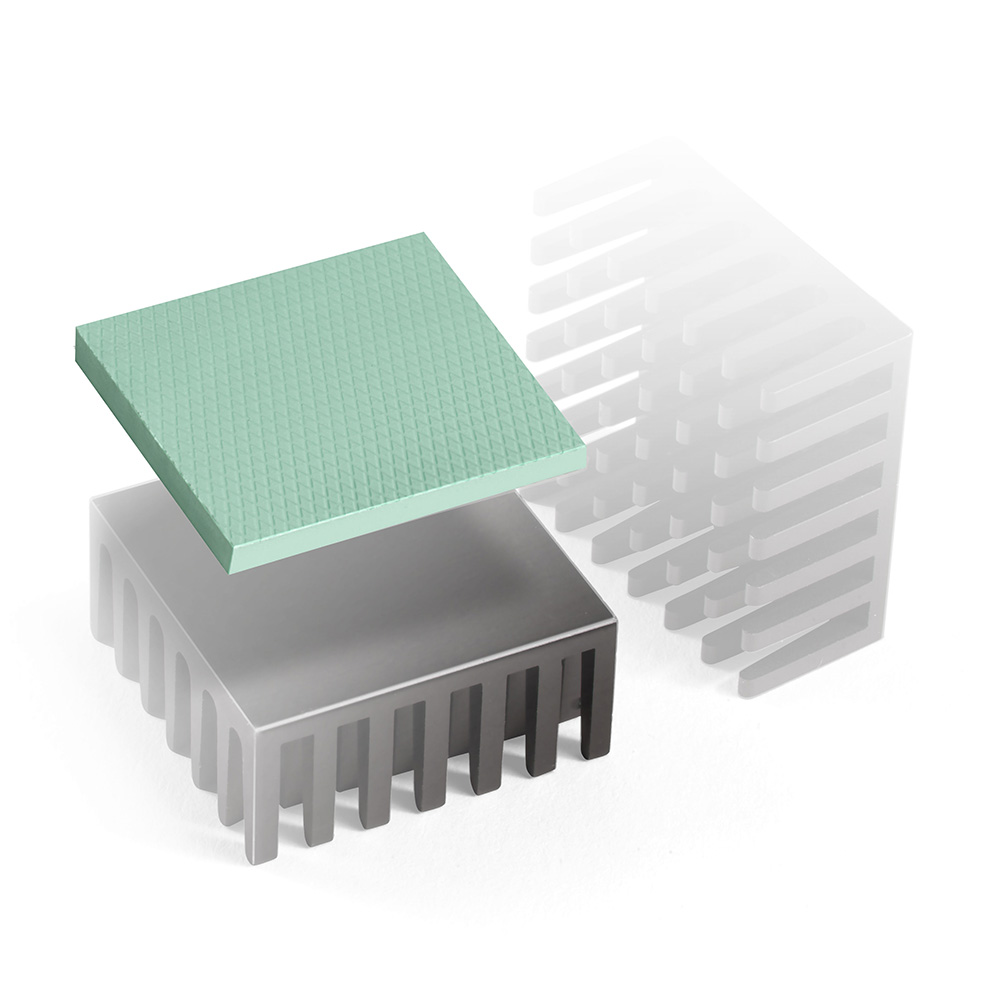

THERM-A-GAP™ thermal gap filler pads are soft and easily conformable to provide thermal interfaces between heat sinks and electronic devices, accommodating for uneven surfaces, air gaps, and rough surface textures. THERM-A-GAP thermal gap filler pads are available in various carrier and liner configurations for increased operating performance and have a soft construction that offers high conformability to reduce interface resistance.

Parker Chomerics THERM-A-GAP PAD 30 Thermally Conductive Gap Filler Pads provide a soft (34 Shore 00) solution with 3.2 W/m-K of thermal conductivity.

Parker Chomerics THERM-A-GAP™ PAD 60 Thermally Conductive Gap Filler Pad is a soft, high performance thermal gap filler pad with 6.0 W/m-K and a Shore 00 hardness of 31.

KRA works with Chomerics THERM-A-GAP PAD 30 and THERM-A-GAP PAD 60 because:

- Created to be the most cost competitive material in the gap filler market

- They offer Ultra low deflection force

- Range of thermal performances available

- High tack surface reduces contact resistance

- “A” version offers high strength acrylic pressure sensitive adhesive for permanent attachment

- Various thicknesses available, finished in standard sheets

- Custom sized configurations and/or cut parts are available as individual parts, or on sheets

When are Chomerics THERM-A-GAP PAD 30 and THERM-A-GAP PAD 60 used?

TYPICAL APPLICATIONS

- Telecommunications equipment

- Consumer electronics

- Automotive electronics (ECUs)

- LEDs, lighting

- Power conversion

- Power semiconductors

- Desktop computers, laptops, servers

- Handheld devices

- Memory modules

- Vibration damping

Case Study:

High Performance Thermal Gap Pad for Smart Home Device

Problem

A global manufacturer of smart home devices required a high thermal conductivity gap filler pad to effectively dissipate heat from a CPU and RAM ICs to a cooling plate within a housing.

Smart home devices are proliferating our everyday world, with popular products from both large multinational technology players and scrappy startups alike, there are endless smart home products available on the marketplace today. With each iteration and design cycle, smart home devices are expected to include more features and achieve greater performance, thus driving the need for increased thermal interface material (TIM) performance.

Critical Material Requirements

- Elastomeric gap filler pad for heat dissipation

- Soft and easily conformable

- Thin, able to be easily die cut to size

- Applied via robotic arm for high volume applications

- Cooling of CPU and RAM

- ICs from metal can to metal housing chassis

Customer Specific Requirements

- Ease of application

- Global availability near manufacturing location

- Pick and place robotic assembly

- Thermal impedance of <0.30 °C-in2/W

- Thickness of 1.5 mm or less

- Thermal conductivity of >5 W/m-K

Solution:

The global manufacturer of smart home devices used THERM-A-GAP™ PAD 60 from Parker Chomerics to effectively dissipate heat from both CPU and RAM ICs.

Parker Chomerics THERM-A-GAP™ PAD 60 is an ultra-soft, ultra-conformable high performance thermally conductive gap filler pad with 6.0 W/m-K thermal conductivity.

Smart devices require thermal gap filler pads to effectively dissipate heat generated not only from dual band Wi-Fi and Bluetooth controllers, but also high-end processors which support many CPU cores and features.

THERM-A-GAP PAD 60, the next generation of thermal gap filler pads from the THERM-A-GAP family of thermal interface materials, was selected as the thermal gap pad solution as it provides an efficient thermal exchange between the processor Integrated Heat Spreader (IHS) and heatsink on smart home PCBs.

Designed with performance in mind, THERM-A-GAP PAD 60 offers a 6.0 W/m-K thermal conductivity and a very low hardness of 31 Shore 00. The Shore 00 hardness scale covers very soft materials like rubbers, foams, sponges, and gels. A 31 Shore 00 result equates to approximately the hardness of a gel-like shoe insole.

Conclusion

THERM-A-GAP PAD 60’s combination of high thermal conductivity and ultra-soft conformability, along with very low NASA outgassing, provides an effective thermal interface between heat sinks and electronic devices where uneven surfaces, air gaps and rough surface textures may exist.