CNC Cutting with KraFAB Precision, efficiency, speed.

What is CNC Cutting?

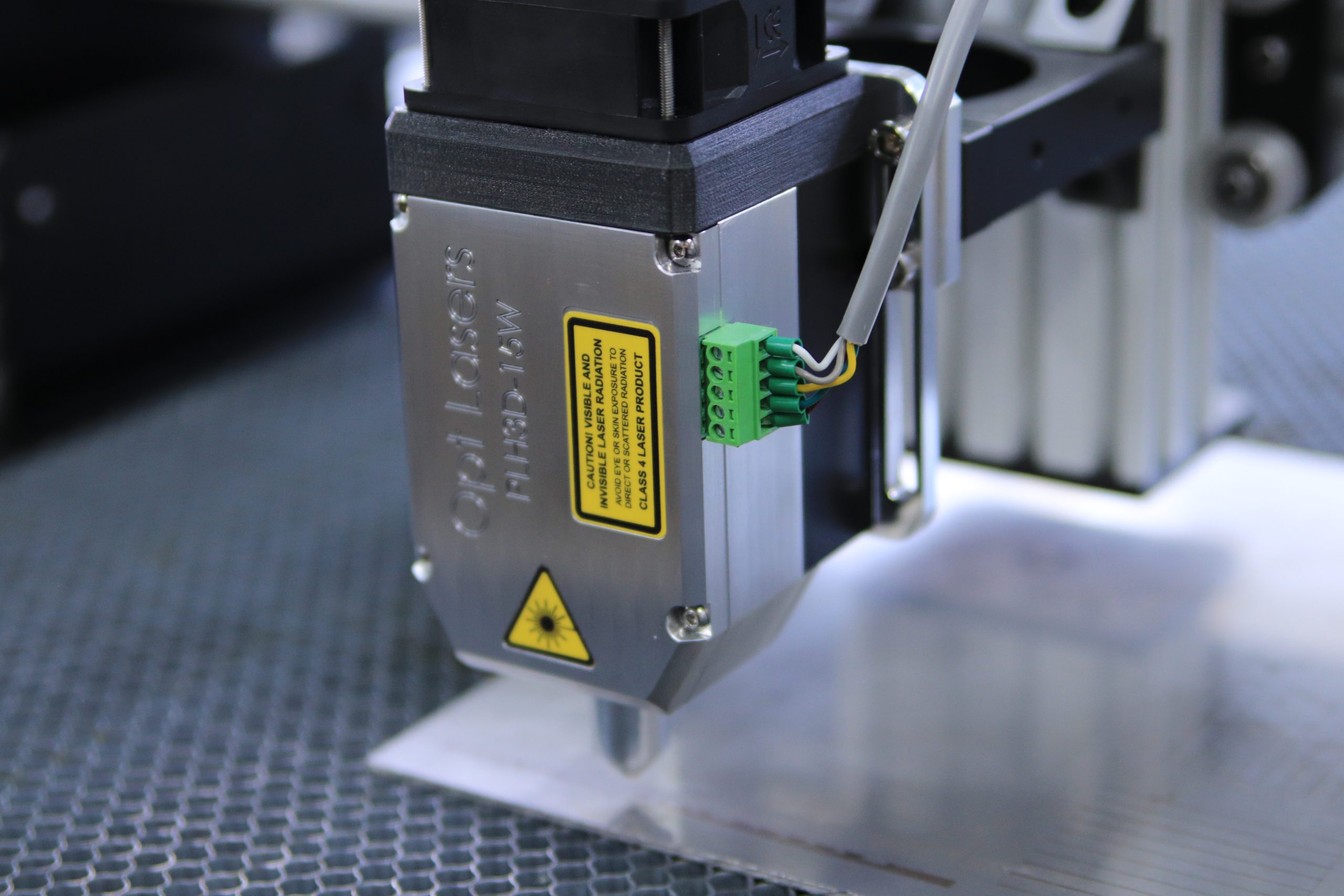

CNC is the acronym for “computer numerical controlled,” regarding machine forming, milling, cutting, and turning. CNC machines act on predetermined programs for specific designs. Compared to 3D printing, which forms a specific material into a shape, CNC knife cutting cuts a shape out of a material. This allows for the use of a wider range of materials and faster processing of parts. There are a few names for this type of machine, including CNC cutting, die-less cutting, digital cutting, and CNC routing.

Under the terminology of CNC routing there are other names to describe the type of digital, automated processing CNC cutting performs: fly-knife, XY, and auto cutting.

Why use CNC?

Use of CNC machines provides a number of benefits, including but not limited to:

CNC Services Offered by K. R. Anderson

CNC Services Offered by KraFAB

Digital cutting with KraFAB process provides you maximum efficiency and cost-effective use of materials. Our advanced understanding of nesting allows us to maximize yields and minimize waste on expensive materials.

CNC cutting is a particularly good choice for prototyping because it allows for rapid turnaround and concept testing. Further, digital cutting applications are extremely adaptable. We can accommodate a variety of dimensional specifications and are able to perform “kiss” cutting–often used for peel-away adhesive products.

When compared to manual techniques, CNC cutting offers a significantly greater degree of complexity for design. Beyond complexity, we provide repeatability–a key component to testing–with our CNC services.

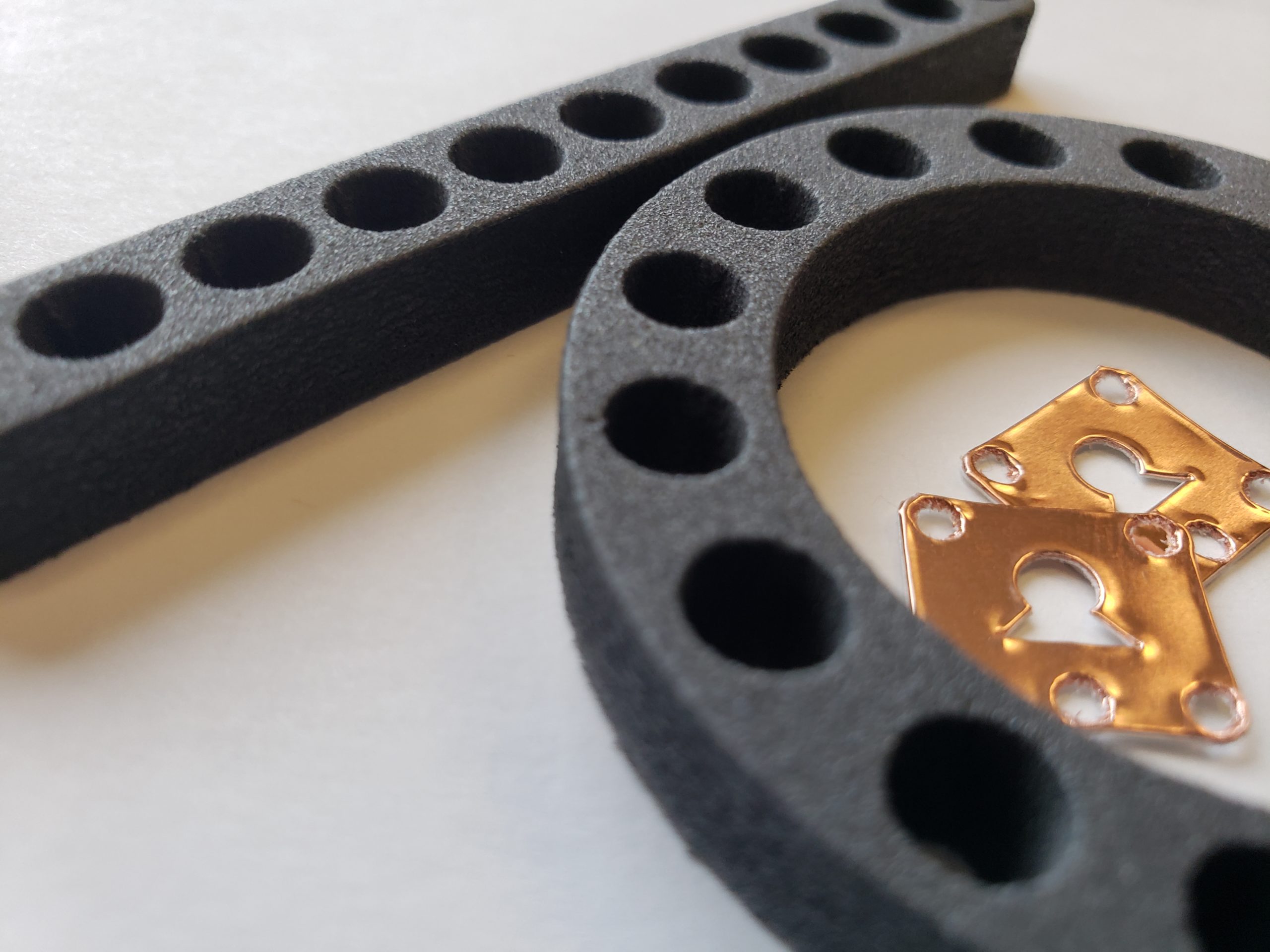

CNC cutting provides fast, repeatable, complex results working with foam, plastics, silicone, rubber, wood, textiles, leather, and even composites like fiberglass and carbon-fiber weaves.

Combining your CNC cutting projects with KraFAB’s form-in-place (FIP) gasket process gives you maximum complexity, control, and reliability in production.

Get a quote

Contact us today for more information on our CNC cutting services.