Chomerics Cho-Shrink

Chomerics CHO-SHRINK is an electrically conductive, heat shrinkable material designed to provide lightweight cable and connector EMI shielding. CHO-SHRINK materials are ideal for applications where weight savings associated with EMI cable shielding is of paramount importance.

Why use Chomerics Cho-Shrink?

The CHO-SHRINK cable shielding system allows for relatively easy assembly of shielding systems for complex cable wiring harnesses using conventional heat shrink tubing heating devices. The system offers excellent shielding and significant weight savings over traditional metal braid cable shielding systems. In addition, CHO-SHRINK offers an environmental shield against dust, moisture and other contaminants.

CHO-SHRINK remains flexible to support any needed cable routing. Easy repair or rework of cables is facilitated by cutting off the CHO-SHRINK material and installing new material. CHO-SHRINK materials are ideal for installation on cabling for medical device electronic assemblies which require reliable EMI shielding performance and may benefit from silver’s antimicrobial properties. Typical applications can include; missiles, aircraft, satellites, vehicles, and on cables of any other electronics systems where weight savings is mandatory.

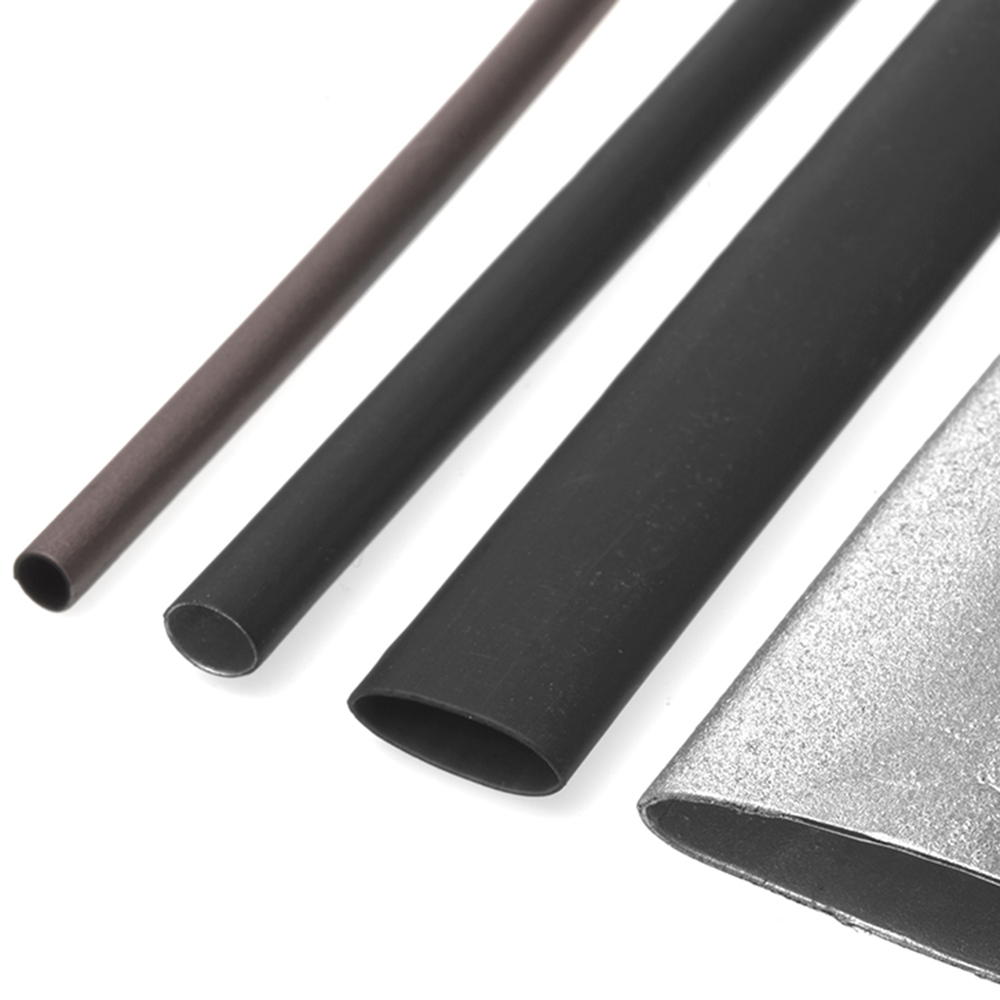

CHO-SHRINK electrically conductive heat shrink tubing is available in two performance options: CHO-SHRINK 1061, coated with silver, designed for higher end military and aerospace applications, and CHO-SHRINK 1120, coated with silver-plated copper, and designed for commercial applications. Both provide lightweight cable and connector EMI shielding with easy installation and assembly by conventional heat guns and ovens.

Features and Benefits:

• Meets NASA outgassing specs for space use

• 50-60 dB attenuation above 500 MHz for CHO-SHRINK 1120, 70-80 dB attenuation for CHO-SHRINK 1061

• Simplifies connector and transition shielding design

• Excellent moisture and contamination seal

• Dramatic weight savings vs. conventional braided mesh

• 4:1 shrink ratio

• Standard lengths for tubing are 4 ft (1.22m)

Typical Applications:

• Medical devices

• Automotive cable assemblies

• Missiles

• Satellites

• Any light-weighting application

Case Study Medical

CABLE ASSEMBLY AND INTERCONNECT SOLUTION MANUFACTURER REQUIRED EMI SHIELDING TO REDUCE RADIATED EMISSIONS

Cables of a life science device needed EMI shielding to improve signal to display monitor.

Customer Challenge

A global manufacturer of medical cables and interconnect solutions needed a technology to reduce radiated electromagnetic interference (EMI) by shielding cable conductors where the main shield was not enough. Not only was the existing cable creating unintended radiated emission problems, but external radiated energy in the environment was affecting the intended video signals within the cable.

An enhanced cable shielding system was necessary to help produce a more vibrant video signal in the display cable. The customer looked for an enhanced EMI/EMC shielding system to help reduce the radiated emissions from the cable and improve video signal integrity in this application.

Design Requirements

- Cable shielding effectiveness performance of at least 50-60 dB attenuation above 500 MHz

- Available in different diameter sizes to give flexibility in choosing cable sizes

- Available cable grounding techniques

- Easy installation and assembly in the field

- Excellent sealing against contaminants and cleaning solutions in a medical setting

- Ability to support manufacturing globally

Key Customer Requirements

- Heat shrink tubing must be available in different diameter sizes

-

Shrink ratio up to 2:1

-

EMI shielding solution needed to be flexible before and after assembly

-

No mechanical hardware required for installation

-

Excellent EMI shielding and method for ground termination

Solution

Typical off-the-shelf heat shrink tubing provides electrical insulation, mechanical protection, and environmental sealing, and is available in a wide range of diameters and sizes giving the customer ultimate design flexibility. But typical heat shrink tubing cannot provide shielding when electromagnetic interference (EMI) or radio-frequency interference (RFI) is needed.

Parker Chomerics CHO-SHRINK® Conductive Heat Shrinkable EMI Cable Shielding System takes the flexibility of a typical polyolefin heat shrink tubing and adds effective EMI/EMC shielding performance.

In this instance, the customer chose to use Parker Chomerics CHO-SHRINK 1120, which is a commercial grade of conductive heat shrinkable tubing, due to its ease to work with and its EMI shielding ability. CHO-SHRINK 1120 uses a proprietary silver-plated copper coating to deliver reliable EMI shielding effectiveness performance of at least 50-60 dB attenuation above 500 MHz.

Conclusion

Parker Chomerics CHO-SHRINK 1120 commercial grade of conductive heat shrinkable tubing, which uses a proprietary silver-plated copper coating to deliver reliable EMI shielding, was chosen for this application. because it was able to successfully reduce radiated emissions.

In addition, improved video signal integrity was achieved by shielding the intended signals within the cable from unwanted external signals. This produced a clearer video signal in the customer’s video display application.

In addition, CHO-SHRINK 1120 is available in many different diameter sizes and is a flexible, easily installed solution which looks professional after installation, which is what the customer preferred.

CHO-SHRINK sizes are also available that are both inside and outside coated with the silver-plated copper coating as well as conductivity coated connector boots. This aids in producing a ground termination system which can incorporate standard connector boot geometries for ground termination through the connector shell.

Additional Resource