Die Cutting Services

When you work with KraFAB for custom die-cutting projects, you get the benefit of our 25+ years of expertise and our state-of-the-art technology. We specialize in custom-cutting shapes to the exact specifications of your design.

It’s our mission to take your design from a drawing to a finished product. We’re your partner every step of the way, and your project is our priority.

What die-cutting services does KraFAB offer?

Die-cutting in manufacturing involves cutting flat parts out of a variety of materials, including rubbers, films, and foams. It’s a great choice for ensuring a uniform product and fast production. It also does not involve heat, so it’s ideal for temperature-sensitive materials.

We’re flexible to work with whatever die-cutting process your project requires. Our custom die-cutting services include:

- Rotary die

- Kiss-cut

- Through-cut of individual pieces

We also offer a wide range of other services, including other cutting techniques. That’s why you can trust us to help select the best method for your unique specifications; we’re not stuck using only a couple techniques. We match the right materials with the right method.

What makes die-cutting from KraFAB better?

Die-cutting is one of the manufacturing industry’s most versatile (and fastest!) production techniques — but depending on the company providing the service, tolerances and precision vary hugely. Because the technology has been around so long (it was pioneered by 19th-century shoemakers and revolutionized the shoemaking industry), there are many companies that offer the service. But many haven’t kept up with the latest improvements and methods that have made die-cutting indispensable to modern manufacturing.

A good die-cutter knows how to reduce beveling, minimize mechanical stress on the material, and ensure the best possible accuracy while balancing your budgetary considerations. With KraFAB, you get both the experience and the up-to-date technical skills your project needs.

The benefits of our die-cutting capabilities include:

- Higher consistency and tolerance

- Ability to work with a wide range of materials

- Extremely precise cutting, regardless of materials, size, or consistencies

- Fast turnaround that works with your timeframe

Our team of experts design die cuts for performance applications. We will walk you through the specs, gasket design, and all other application considerations to ensure that your die cut gasket will function as intended. KraFAB’s attention to design and planning means that you’ll receive the right die cut, on time, and on budget.

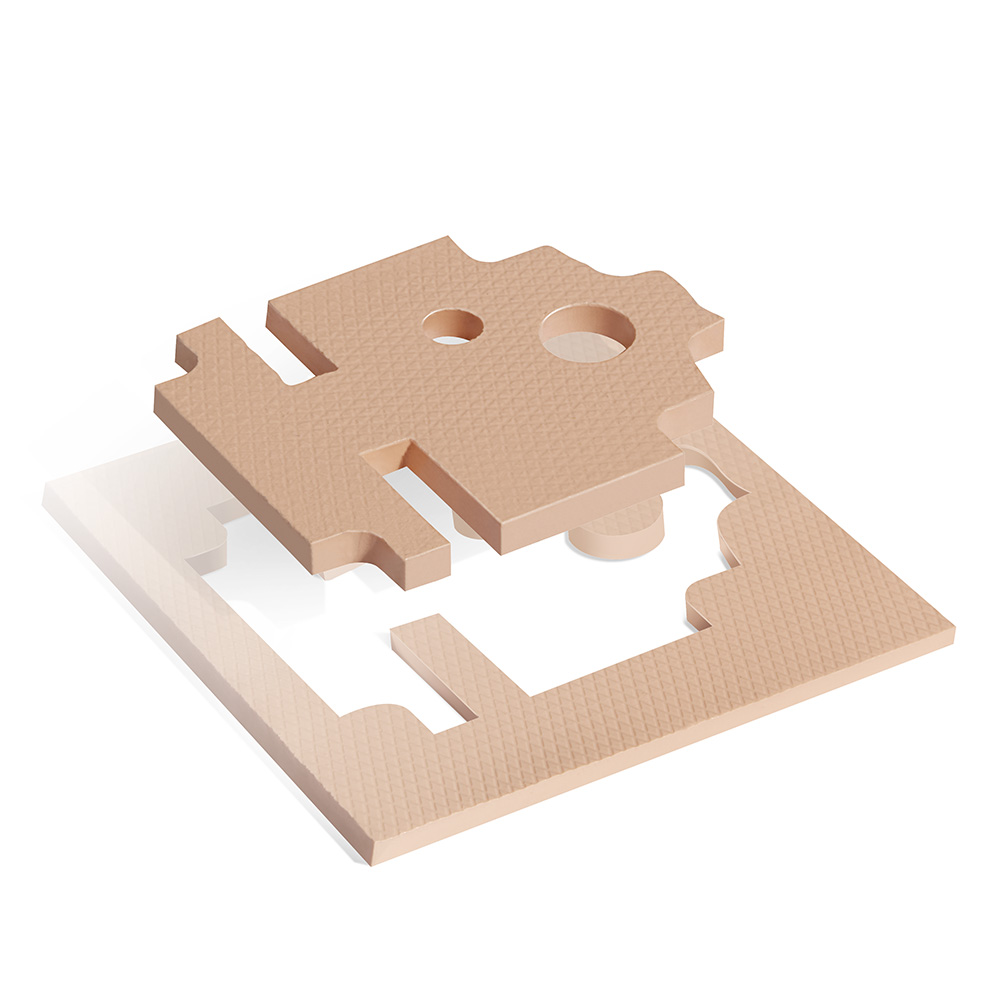

Planning ahead to create the right die cut for your application means avoiding some common mistakes in design. Oversights in die-cut design can be costly and detrimental to the application. Below are some of the most common mistakes and how to avoid them:

Mistake #1 Die Cut Gasket Design Challenges

Die cutting supports both nested parts and any design that requires punched holes or slots with specific radii for fasteners. A common but costly mistake is forgetting to consider bolt constraints during the design phase.

Solution

Early in the design process, it is key for an expert converter to identify and adapt to potential manufacturing issues. Waterjet cutting or other alternative manufacturing methods can be considered to avoid costly project delays.

The design can also specify an open slot instead of a hole, or a thinner gasket material to reduce the thickness of the wall between the hole and the edge of the gasket.

Top Tip:

Even if a gasket is drawn and designed to perfection, one hole placed too close to the edge can wreak havoc. The typical steel rule die needs both steel rule and punches to properly cut a gasket with holes. Problems occur when there is not enough room between the hold punch and the steel rule to extract the gasket material from the die.

Mistake #2 Not Auditing Gasket Converter

Cost is a major driving force behind the design. A low cost supplier will always be a tempting option. While there is nothing wrong with saving money, do your due diligence to audit and ask questions of your provider. Neglecting to do so can lead to more cost in the long run.

Solution

Ensure that your supplier has documented processes in place for product quality by using a system certified to an international standard. Make sure that your supplier is also a cultural fit for your organization. Issues in production or quality will arise, and checking authentic references and documented values can help you make a wise choice.

A supplier should also be committed to a clean and well organized manufacturing facility using only the highest quality materials. Especially important is to check that your supplier is not using expired adhesives to make your gaskets.

Top Tip

KraFAB will exceed your expectations when it comes to gasket design and expertise. If you’re looking for a supplier with experience, quality, and great service, contact us today.

Precision of our die-cutting services

Our die cutters are specially manufactured to convert custom-cut pieces to the exact specifications of your design. We know that if production falls outside the tolerances you’ve allowed for, the entire product can be jeopardized, so precision is paramount.

KraFAB offers tight tolerances at reasonable rates. We’re able to promise a fast, reliable, precise final result.

Flexibility to work with the best materials

Your material choice shouldn’t be limited by die-cutting capabilities! That’s why we work with a wide range of materials, which we can cut into any dimension or shape to suit your needs.

We work with a huge variety of materials, including:

Our high-quality materials are manufactured by premier suppliers (including Chomerics, Alpha Advance, Nitto, and Saint-Gobain). We have experience working with these materials and can advise you on the best selection for your needs. Everything is chosen to fit your precise specifications. Of course, we can also convert the products or materials you supply. It’s up to you!

Your design, realized

We can produce our die cuts from spec sheets, hand sketches, or CAD data — however your team works best. We also offer prototypes and samples to ensure that the finished product is exactly what you’re looking for. It’s our firm belief that our clients should always be happy with our work, which is why we’re dedicated to getting it right.

Exactly what you want, just when you need it

From your initial design to the finished product, we’re with you every step of the way. It doesn’t matter if you’re looking for a short run or a high-volume job, or if you need intricate kiss-cutting or a large number of through-cuts. We’re focused delivering the fast turnaround your business needs at cost-effective prices that make smart business sense.

KraFAB has an ISO 9001 certification, which is set by industry standards and the government.

Want to learn more?

If you’re interested in our die-cutting services, the next step is to get your quote. It only takes a few minutes, and a real expert from our team will be in touch shortly to hear more about what you need and how we can help.