High-Performance Foil Laminate Solutions

At KraFAB, we specialize in providing high-performance foil laminate solutions tailored to your industry needs. Whether you’re working in aerospace, electronics, or automotive sectors, our laminating foils offer the durability and precision required for demanding environments. These materials are essential for shielding, heat resistance, and protecting sensitive components.

Overview of Laminating Foils

Laminating foils are thin layers of metal or metallic film designed to protect, enhance, or add functionality to substrates. With applications across various industries, these foils deliver the strength and resilience necessary for everything from EMI shielding to thermal insulation. Our foil laminate products, including aluminum foil, are engineered to withstand extreme conditions and provide long-lasting results.

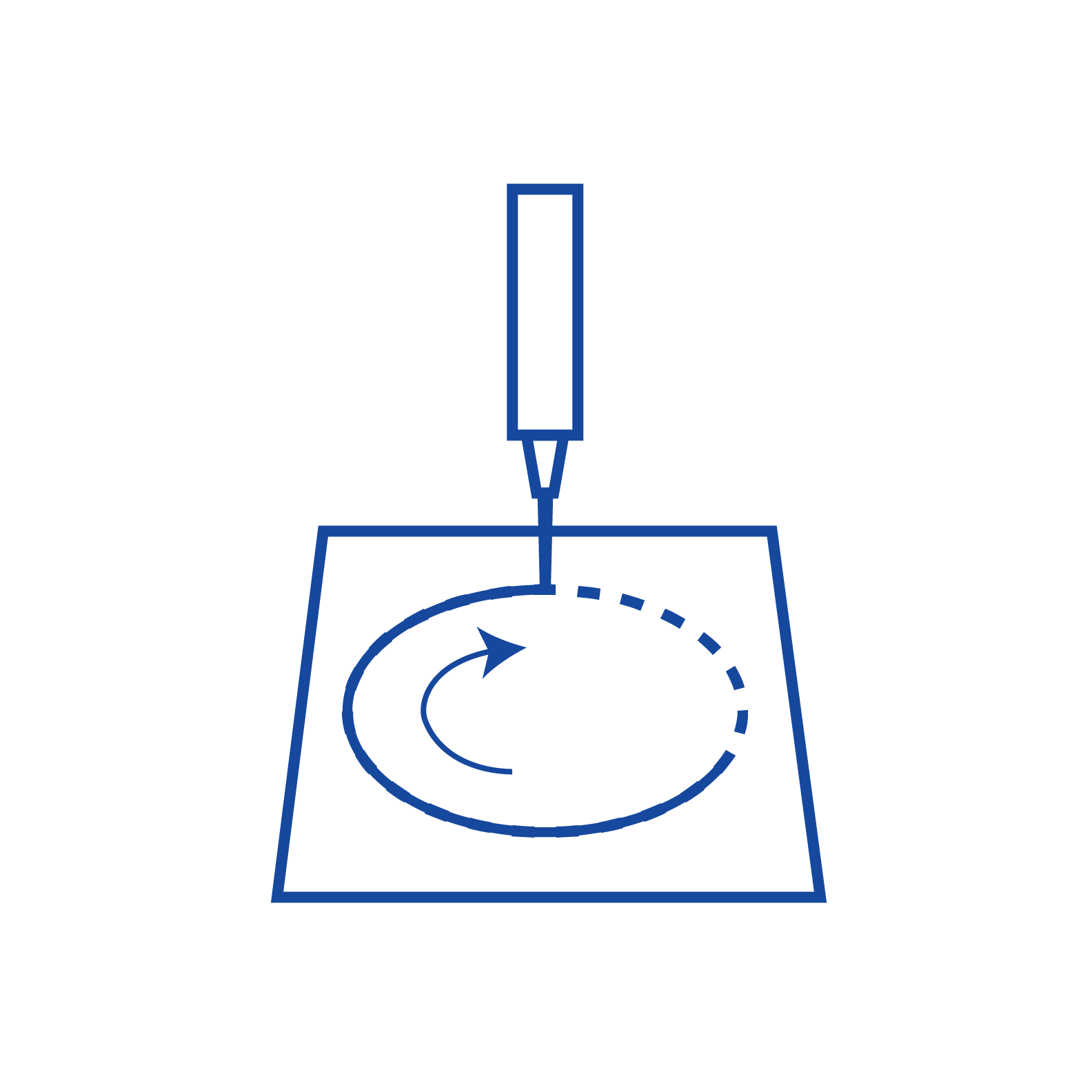

Understanding the Foil Laminating Process

The foil laminating process involves bonding thin layers of metal, like aluminum foil, onto various substrates. This is done through a laminating machine that applies heat and pressure, ensuring a secure and precise attachment. The foil laminating process enhances the material’s protective qualities and adds functional properties such as thermal resistance and conductivity.

The Benefits of Using Laminated Foils

- Protection: Laminated foils provide an extra layer of defense against environmental factors such as moisture, heat, and electromagnetic interference.

- Durability: With high resistance to wear and tear, foil laminates enhance the longevity of your products.

- Versatility: Our laminating foils can be customized for a variety of applications, including aerospace, electronics, automotive, and beyond.

Foil Lamination: A Vital Component in Modern Manufacturing

Foil lamination is more than just a protective measure—it’s a critical element in modern manufacturing processes. By adding foil laminates to your materials, you can enhance product performance, extend the lifespan of components, and meet industry regulations. Our foil laminating services include in-house customization, ensuring that each layer is precisely applied to meet your needs. Whether you’re working with thin films or robust metal layers, KraFAB has the expertise to provide top-tier results.

Key Applications of Foil Laminate Products

- Aerospace: Foil laminates are essential for protecting electronics and sensitive systems from electromagnetic interference and extreme temperatures. Our solutions meet stringent aerospace standards for reliability.

- Electronics: Effective foil laminate materials ensure protection and longevity for electronic components by providing a barrier against environmental factors, such as heat and moisture.

- Automotive: Foil laminates are used for heat management and electrical insulation in vehicles, contributing to both safety and efficiency.

Custom Laminating Foil Options for Your Industry

At KraFAB, we understand that every project has unique requirements. That’s why we offer customized foil laminate solutions tailored to your specific needs. Whether you need laminates for high-temperature environments or specialized electrical applications, our team works closely with you to design a solution that meets your exact specifications. We supply foil laminates in a wide range of thicknesses, materials, and finishes to ensure your project’s success.

Explore Our Full Range of Laminating Foils and Films

At KraFAB, we offer an extensive selection of laminating foils, including thermal and reactive foils, designed to meet the specific demands of your industry. Whether you need foil laminate products for protective coating, heat resistance, or conductivity, our diverse product range ensures you’ll find the perfect solution. Contact us today to discuss your project, and let our team guide you to the best foil laminates and films for your needs.

Why Choose KraFAB?

With years of experience, KraFAB is your trusted partner in foil laminates and films. We offer a comprehensive range of products, from thermal foils to coated films, and provide expert guidance to help you choose the best solution for your application. Our commitment to quality ensures that every foil laminate we produce meets the highest standards of performance and durability.