Tips for Proper Maintenance and Longevity of Form-in-Place Gaskets

Form-in-Place (FIP) gaskets are thick liquids used on substrates to create a durable seal of any size and shape between two surfaces like metal, glass, or plastics. These gaskets are typically made from silicone or other elastomeric materials and are applied directly onto the mating surfaces. To ensure the longevity and effectiveness of FIP gaskets, proper maintenance is essential. Here are some tips to help with gasket application and maintenance FIP gaskets and extend their lifespan:

1. Clean and Prepare Surfaces

Before applying an FIP gasket, it is crucial to clean and prepare the surfaces properly. Because FIP gaskets are applied as a thin layer of liquid that precisely fills the space it needs to within very small spaces (measured to the thousandths of an inch!), any debris or dirt in the way can cause problems with the sealant and adhesion process. To ensure the FIP gasket creates a proper adhesive, remove any dirt, grease, or debris that may hinder the final adhesion of the gasket. Air pockets and large gaps left by dirt and debris on the material surface may result in a failed seal. Use a suitable solvent or cleaner recommended by the gasket manufacturer to ensure a clean and dry surface.

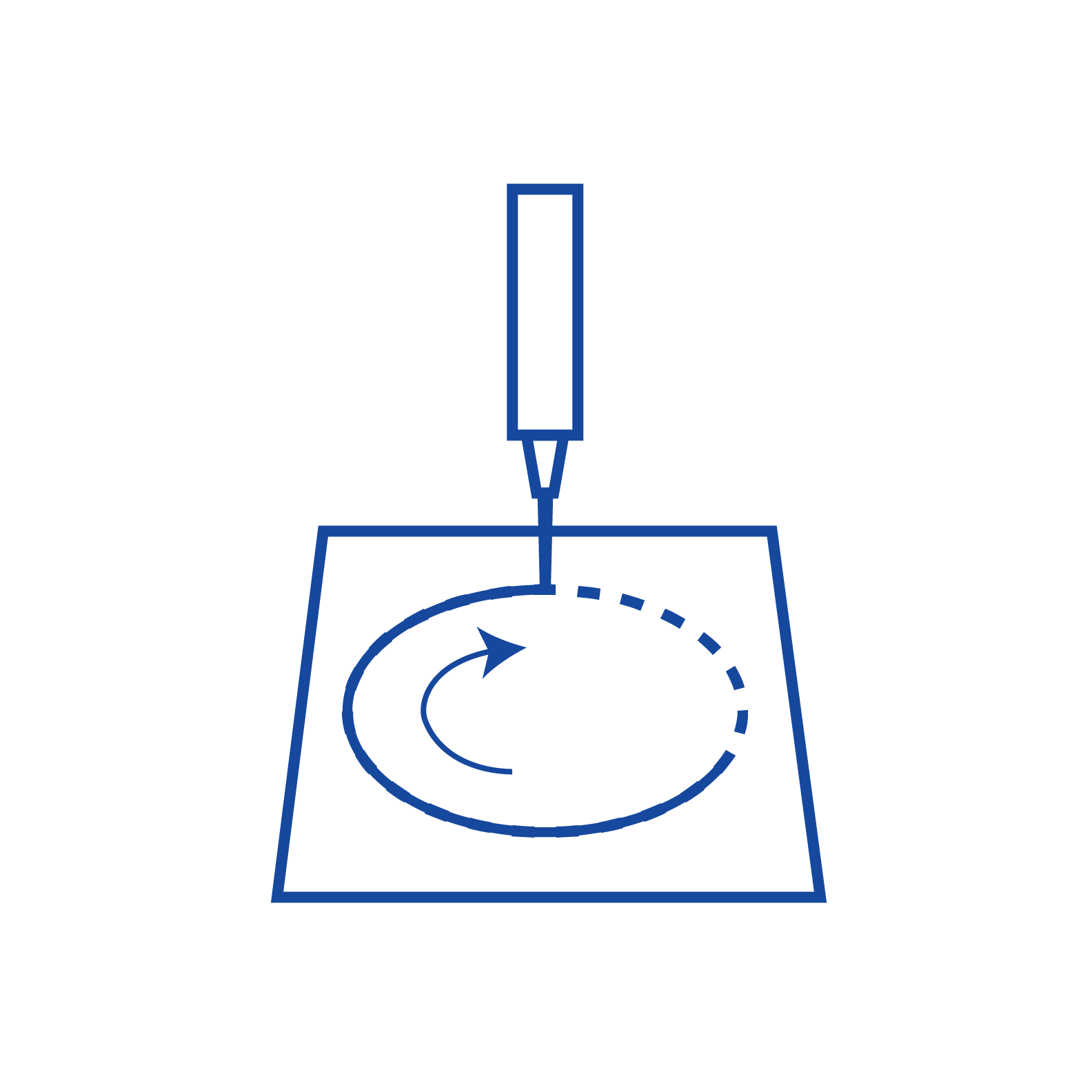

2. Apply Gasket with Precision

When applying the FIP gasket, it is important to follow the manufacturer’s instructions carefully. Apply the gasket evenly and with precision to ensure proper coverage and a consistent seal. Avoid over-applying or under-applying the gasket material, as this can affect its performance. In addition to proper application of the gasket, having the appropriate materials is an important part of the application process. Help ensure that your gaskets are made with high quality products to create better resistance to leakage and ensure the product maintains a strong seal for as long as possible.

3. Proper Curing Time

One of the most common gasket application mistakes is rushing the curing time. To avoid gasket failure, allow the FIP gasket to cure for the recommended time specified by the manufacturer. Curing time ensures that the gasket material fully adheres and forms a strong bond with the surfaces. Rushing the curing process can lead to reduced effectiveness and premature failure of the gasket. Ensuring a full cure minimizes the chance of a corrosion and reduces the chance that the seal will deteriorate before the end of its lifespan.

4. Regular Inspection

Wear and tear is natural and expected with FIP gaskets, making regular inspection a necessary part of proper gasket maintenance. Periodically inspect the FIP gaskets for any signs of wear, damage, or deterioration. Look for cracks, tears, or areas where the gasket might have separated from the surface. By staying on top of gasket maintenance, you can ensure the continued reliability and effectiveness of your equipment. If any issues are found, it is crucial to promptly repair or replace the gasket to maintain its ability to seal. It is also essential to keep the gasket surfaces clean and free of debris to prevent premature wear. Following the manufacturer’s guidelines for installation and maintenance is important to ensure optimal performance of the gaskets for as long as possible.

5. Protect from Extreme Conditions

Because gaskets are used with complex electronics to create environmental seals and to create electromagnetic interference (EMI) shields, it is common for them to be exposed to various environmental factors such as high temperatures, moisture, chemicals, or UV radiation. It is important to ensure proper installation of the gaskets as well as making sure to ensure the compatibility of the specific type of FIP gasket and product that you are applying it to. Shielding gaskets or using protective coatings and enclosures is imperative to increasing the lifespan of the gasket.

6. Follow Manufacturer Recommendations

Always refer to the manufacturer’s guidelines and recommendations regarding storage, handling, and maintenance of FIP gaskets. Each type of gasket can have specific requirements that must be followed to ensure optimal performance and durability. Failure to follow manufacturer recommendations may result in premature wear, leakage, or other issues that could affect the effectiveness of the gasket and potentially cause equipment failure. It is important to carefully read and understand the manufacturer’s instructions and take the necessary steps to comply with their recommendations. This will help to prolong the life of the gasket and ensure its proper functioning in the intended application.

If you have any questions or concerns about the manufacturer’s recommendations, it is best to consult with the manufacturer directly for clarification.

7. Train Employees

If using FIP gaskets in an industrial setting, it is important to train employees on proper handling and maintenance procedures. Educate them about the importance of following guidelines and maintaining a clean working environment to prevent contamination or damage to the gaskets. You can start by familiarizing your employees with the types of FIP gaskets used in your facility and their specific applications. Ensure they understand the importance of using the correct gasket for each application to prevent leaks and maintain equipment integrity.

Further, you’ll want to teach employees how to properly clean and inspect gaskets and the surrounding equipment to prevent issues or to address any issues found during routine inspection of the gaskets. Provide employees with guidelines and procedures for handling FIP gaskets, including storing them in a clean and controlled environment, using recommended cleaning agents, and handling them with care to prevent damage or contamination.

Importance of Proper Maintenance for Form-in-Place (FIP) Gaskets

By following these tips for proper maintenance of Form-in-Place gaskets, you can ensure their effectiveness and extend their lifespan. Regular inspection, careful application, adherence to curing times, and protection from extreme conditions are key factors in maximizing the performance of FIP gaskets. Always consult with our engineers at KraFAB for specific recommendations for your particular application.

Contact KraFAB to discuss your specific project and its requirements.

Choose KraFAB for Unmatched Responsiveness, Flexibility, and Timely Delivery of FIP Gaskets

By choosing KraFAB as your partner for FIP gaskets, you benefit from their responsiveness, flexibility, expertise, and commitment to meeting your unique needs. With their extensive capabilities and customer-centric approach, KraFAB is the best choice for all your FIP gasket requirements. Trust KraFAB for unmatched quality, reliability, and service excellence in the world of FIP gaskets.

To further delve into the details and take advantage of our decades of experience, please contact KraFAB.