The Future of Form-in-Place Gaskets: Trends and Innovations in the Industry

Form-in-Place (FIP) gaskets have been a crucial component in various industries, providing reliable sealing solutions for applications with complex geometries. As technology continues to advance, the future of Form-in-Place gaskets looks promising, with innovative trends shaping the industry. In this blog post, we will explore some of these trends and discuss how they are revolutionizing the field in 2024 and beyond.

1. Advanced Materials for Enhanced Performance

One of the significant trends in FIP gasket technology is the development of advanced materials that offer enhanced performance characteristics. Manufacturers are continually exploring new materials with improved resistance to extreme temperatures, chemicals, and environmental factors. These materials not only provide better sealing capabilities but also increase the lifespan of FIP gaskets, making them more cost-effective for various applications.

As the market size for form-in-place gaskets grows, there is an increased demand for sustainable solutions and increased awareness about the need for eco-friendly products, particularly in the automotive industry. Manufacturers are working on developing FIP gaskets made from advanced materials that are recyclable and contribute to reducing carbon footprint.

Furthermore, the integration of smart technology is also becoming a prominent trend in FIP gasket technology. This includes the development of gaskets embedded with sensors for real-time monitoring of predictive maintenance, performance, and durability. Such smart gaskets offer the advantage of early detection of potential issues, leading to proactive maintenance and reduced downtime.

2. Miniaturization and Micro Gaskets

The FIP gaskets industry has experienced significant market growth due to the growing demand for smaller and more compact devices. A surge in the development of micro gaskets that can provide reliable sealing solutions for miniature components has shown just how fast these industries are growing, and how important FIP gaskets are to these various industries.

These tiny gaskets are designed to fit into tight spaces without compromising on performance, making them ideal for applications in various industries such as automotive, electronic, and medical devices. Non-conductive and conductive form-in-place gaskets provide a leak-proof shield from electromagnetic interference (EMI) and environmental sealing that is paramount for use in these industries and is expected to see continued growth in the global market.

3. Smart Gaskets with Sensor Technology

The integration of sensor technology into FIP gaskets is another exciting trend in the industry. Smart gaskets equipped with sensors can provide real-time data on factors like temperature, pressure, and vibration. This data can be crucial for monitoring and predictive maintenance purposes, allowing proactive measures to be taken to prevent equipment failures or leaks. Smart gaskets are expected to find applications in a wide range of products in industries such as aerospace, manufacturing, and energy.

When considering the future of smart gaskets, it’s important to consider how smart technology has already changed market dynamics in these sectors, looking at past industry trends and market forecasts.

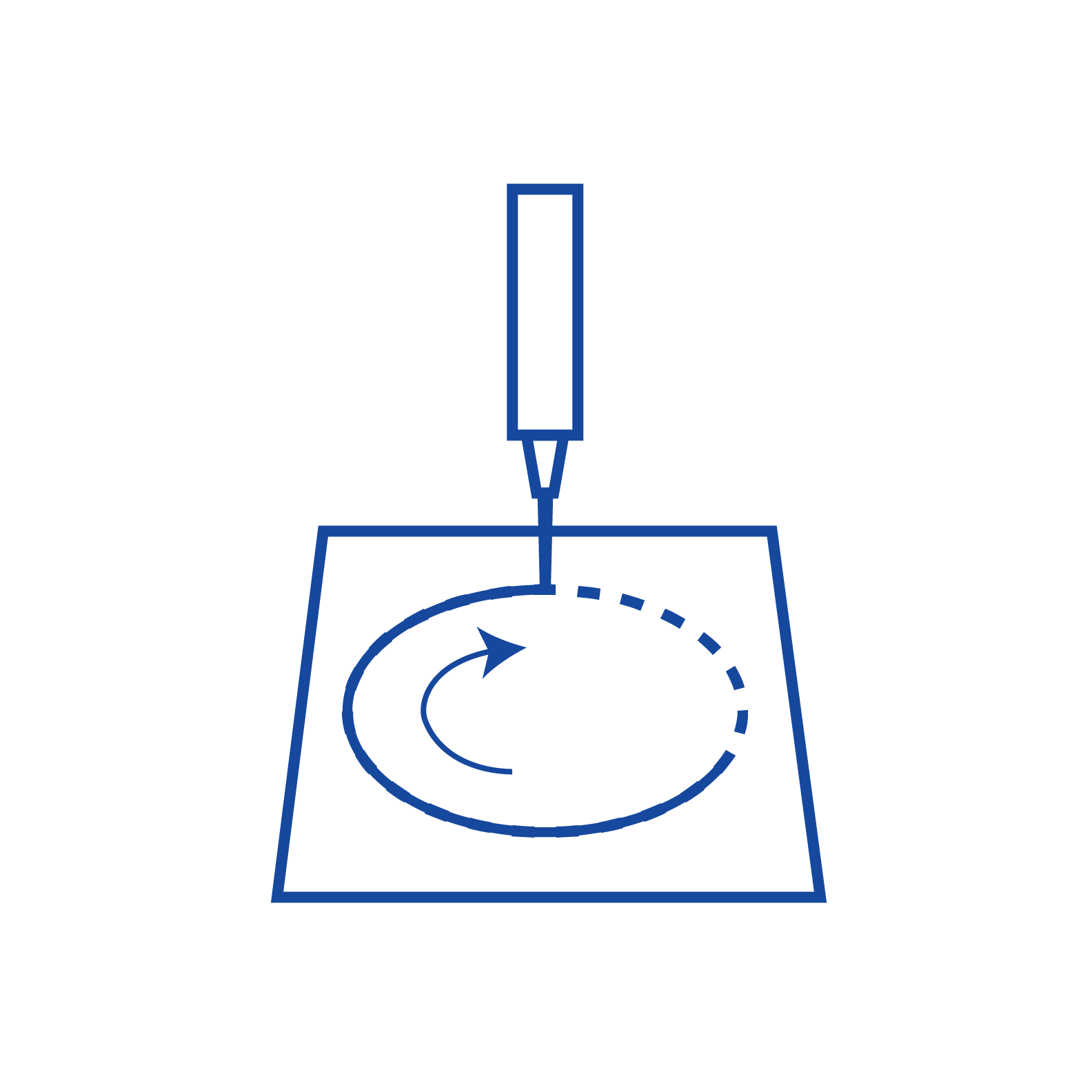

4. Automation and Precision Application

Automation has revolutionized many industries, and FIP gasket application is no exception. Manufacturers are increasingly adopting automated systems for precise deposition of gasket materials. Innovative techniques such as precision molding, 3D printing, and automated assembly are being employed to produce gaskets with higher precision and consistency. This not only ensures better performance but also streamlines the production process, leading to higher productivity and cost-efficiency. This ensures consistent quality and eliminates human error during the application process. Automated systems also allow for faster production rates, reducing lead times and increasing overall efficiency.

5. Eco-Friendly and Sustainable Solutions

As sustainability becomes a global priority, the FIP gasket industry is embracing eco-friendly and sustainable solutions. Manufacturers are developing gasket materials that are recyclable and biodegradable without compromising on performance. Additionally, efforts are being made to reduce waste during the production process by optimizing material usage and implementing recycling programs.

The use of renewable energy sources and the implementation of energy-saving technologies are becoming standard practices within the industry. This not only reduces the carbon footprint of production but also lowers operational costs, making eco-friendly gaskets a financially viable option for businesses. The future outlook of the market viability of eco-friendly FIP gasket solutions is positive, and it will be important to continue watching market forecasts as the technology grows.

The Promising Outlook for Form-in-Place Gaskets

The future of Form-in-Place gaskets is brimming with innovation and exciting possibilities. Advanced materials, miniaturization, smart gaskets, automation, and eco-friendly solutions are some of the key trends shaping the industry. As these technologies continue to evolve, we can expect FIP gaskets to provide even more reliable and efficient sealing solutions for a wide range of applications.

Overall, the FIP gasket technology is evolving to meet the ever-increasing demands for improved performance, sustainability, and efficiency. As manufacturers continue to invest in research and development, it is expected that the FIP gasket market is expected to witness greater growth as even more advanced materials, sustainable manufacturing practices, and smart technologies come into play.

Contact KraFAB to discuss your specific project and its requirements.

Choose KraFAB for Unmatched Responsiveness, Flexibility, and Timely Delivery of FIP Gaskets

By choosing KraFAB as your partner for FIP gaskets, you benefit from their responsiveness, flexibility, expertise, and commitment to meeting your unique needs. With their extensive capabilities and customer-centric approach, KraFAB is the best choice for all your FIP gasket requirements. Trust KraFAB for unmatched quality, reliability, and service excellence in the world of FIP gaskets.

To further delve into the details and take advantage of our decades of experience, please contact KraFAB.