6 Proven EMI Gaskets To Effectively Shield Interference

What EMI gasket is right for your application?

Electromagnetic Interference (EMI) gaskets play a critical role in safeguarding electronic devices and systems from the disruptive effects of unwanted electromagnetic signals. As electronic devices become more intricate and sensitive, the need for effective EMI shielding solutions has grown. To cater to the diverse requirements of EMI shielding, a variety of EMI gasket types have been developed, each meticulously designed to tackle specific shielding needs and application contexts. This article offers an in-depth exploration of these different EMI gasket variants, shedding light on their distinctive attributes and optimal use cases.

In the realm of EMI shielding, a one-size-fits-all approach simply doesn’t suffice. Electronic devices span a wide spectrum of shapes, sizes, functionalities, and environments. Consequently, EMI gaskets are tailored to cater to this diversity, ensuring that each specific shielding challenge is met with a precise solution. From the intricate inner workings of electronic enclosures to connectors, cables, and beyond, EMI gaskets are strategically employed to create a barrier against the intrusion or escape of electromagnetic interference.

1. Form-in-Place

Form-in-place gaskets are one of our specialties. The form-in-place gasket is an electromagnetic interference shielding solution that can be automatically dispensed with optimal precision and minimal manual labor. In 1997, K. R. Anderson was one of the first to use automated FIP gasketing technology, and our tenured team has mastered the practice ever since.

Originally, FIP gaskets were used for applications that involved inter-compartmental isolation to separate signals from other processing units. That said, they’re still best-suited for small form applications, as their beads can be distributed in smaller sizes than other gasketing solutions (0.018” tall by 0.022” wide).

The FIP gasket is automatically applied, so a simple CAD model can be programmed into the dispensing system to guide the most precise path in for the gasketing, reducing the need for manual labor and thereby preventing any human error during the dispensing process.

Other valuable benefits of form-in-place gaskets include:

- Spatial efficiency

- Highly compressible gaskets

- Rapid turnover for design changes, prototyping and sampling

- Cost-efficient design and manufacturing

2. Fabric Over Foam Gaskets

For applications that require a low amount of compression force, fabric-over-foam (FOF) gaskets are an ideal solution. While low force is one of its most valuable features, FOF gaskets also offer high conductivity and shielding attenuation, making it an effective shielding solution for a wide range of frequencies. The gaskets can suit a variety of tolerances depending on the application at hand, but this gasket style is particularly well suited for lighter materials. The FOF gasket is commonly used for electronic enclosure sealing applications.

Fabric-over-foam gaskets are preferable for teams looking to save on cost without sacrificing quality. These gaskets require minimal tooling which prevents the need for excessive start-up costs. The conductive fabric is oxidation-resistant, helping it ensure long-term functionality.

Typical applications for fabric-over-foam gaskets include:

- Between screws and chassis

- On heat sinks

- Panel, cover and door seals

- Grounding tabs

- Vent seals

- Improved ground paths

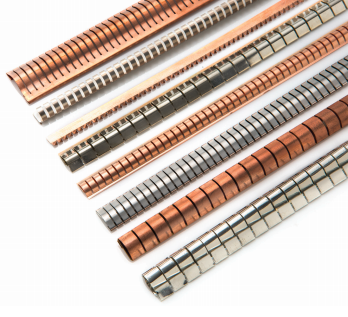

3. Fingerstock Gaskets

Fingerstock gaskets are typically used when the gasket is involved in a wiping or swiping motion of its corresponding application, such as in a sliding door. It is also used when there’s a risk of oxide build-up on the contact surfaces. It’s often the right choice when the application will mean the part is opened and closed repeatedly.

These gasket styles are known for their low contact resistance between joined surfaces of components. This helps to provide tremendous EMI shielding for several applications, filling gaps of various sizes without compromising the efficacy of the shielding properties.

While finger stock gaskets are typically made of copper material, variations include plated finishes of tin, zinc, nickel and other conductive materials to suit several applications. They may also vary in terms of size, design features and mounting methods.

Common mounting methods for finger stock gaskets include: self adhesive clip on rivet mount slot mount solder in place

Finger stock gaskets do, in fact, suit a wide range of applications, but environmental adversities can cause damage to the gasket and impair performance. They should always be used in applications where they’re protected from external environments that propose a threat to the device, or in more moderate environments altogether.

4. Knitted Wire Mesh Gaskets

Used to seal lids, doors, and more. They have the benefit of being resistant to corrosion, abrasion, and high temperatures. Additionally, they’re extremely durable, holding up over time and resisting wear. Use knitted wire mesh gaskets when you need high EMI/RFI shielding, as well as low-frequency magnetic shielding.

Knitted wire mesh gaskets are some of the most durable gaskets available, serving several types of high intensity applications with ease due to its steel mesh exterior.

These gaskets are most commonly made from stainless steel or tinned copper steel wiring to protect the internal core while also offering flexibility in the realm of application and design.

The wiring may also consist of Morel, a nickel-copper alloy. As the wire mesh is flexible and can be molded around the frame of many different shapes of materials, this gasket style suits applications that are rounded, rectangular, double round and more.

The metallic wire encloses the core, which is typically made of rubber, foam or elastomers. Wire mesh gaskets are used most commonly in magnetic and electrical fields.

5. EPDM Rubber Gaskets

EPDM (ethylene-propylene-diene-monomer) gaskets are made of a synthetic rubber suitable for a wide range of applications.

Given that these gaskets are rubber-based, they’re an ideal gasketing solution for applications that face environmental climate fluctuations (ie: ozone, climate, sunlight, aging, some types chemical exposure, etc.), such as in the automotive or construction industries. Common conditions that EPDM gaskets fare well under include air, hot water, cold water and steam.

These gaskets are typically used for projects that involve glazing, such as window and door sealing, but their capacities range broadly across several industries.

6. Conductive Elastomer Materials

Once used mainly to shield critical defense and aerospace electronic systems, conductive elastomers have become the progressive choice for multiple uses. Some of the ideal applications for conductive elastomer materials include telecommunications, automotive, industrial equipment, and medical devices.

Conductive elastomers are ideal for reliability over the life of the equipment. The same gasket is both an EMI shield and an environmental seal. Elastomer gaskets resist compression set, accommodate low closure force, and help control airflow. They’re available in corrosion-resistant and flame-resistant grades, as well as have aesthetic advantages.

Take a deep dive into learning more about conductive elastomers design.

Integrated Solutions for Electronic Housing

KraFAB can supply a complete single source solution to your EMI shielding needs in plastic housing. If the device requires a display filter, we can design and supply one using the latest technology. The filters can provide EMI shielding and improve visibility in any environment. The display filter may be incorporated into the housing or bezel, so it’s ready for assembly.

EMI shielding gaskets can be added as an integral part of the housing of all gasket technologies. If thermal management materials are needed, KraFAB can supply heat sinks with thermal interface materials integrated into the housing. Non-conductive thermoplastics are available with secondary EMI coatings, dependent upon the needs of the application.

Backed by Decades of Industry Experience

We can guide you toward the most cost-efficient, easily fabricable product on the market.

If you find yourself navigating the complex landscape of EMI gasket selection and have questions about identifying the perfect shielding solution for your specific needs, we’re here to help. Our dedicated team of experts is ready to assist you in making informed decisions tailored to your requirements.

We understand that every application is unique, and our commitment is to provide personalized support to help you select the optimal EMI gasket that aligns seamlessly with your project. Your questions matter, and we’re eager to assist you on your journey to effective EMI shielding.